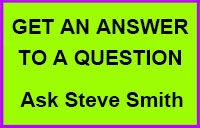

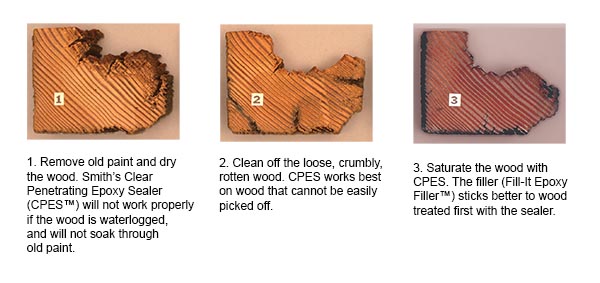

The restoration process is simple and easy to do.

Painting contractors can do it quickly and easily. Homeowners

commonly do it themselves. The restoration process is illustrated here: Six Steps

to Restoration with Smith's Clear Penetrating Epoxy Sealer. The first three steps are explained below: Here's One Reason Why This Is The Only Technology That Works: Here's Proof: Here's Another Reason Why: Here's Proof: Here's How an architect can specify the products for

Restoration or for

Painting. Here's More Proof: Here's Another Reason Why: Wood naturally contains water, typically 8% to 15%, even 25% or more in humid environments such as around boats

or in chronically humid climates. The solvent system that carries the natural wood resins of Smith's Clear Penetrating Epoxy Sealer

into the wood has to be capable of dissolving that water, so that the penetration show in the prior examples can happen. Products

made using water-repellent petrochemicals such as benzyl alcohol cannot do this. None of Smith's products use benzyl alcohol. Here's Still Another Reason Why: How did Steve Smith come to invent this? Here's Steve Smith to tell you in his own words: Being a chemist and a physicist, I was able to approach the problem of wood rotting and paint failing

scientifically, which no one else in this or any related business ever did; there were and are many people making epoxy

products, but none of them had a comparable background and were able to approach the problem by identifying the root causes

of wood failure and product failure. Peeling paint and rotting wood on wood building exteriors has been common since buildings were first made of wood;

there never-before has been a truly effective solution. The conventional maintenance for peeling paint consisted of scrape, putty

and paint, and again in a few years scrape, putty and paint. No one realized that the wood fibers themselves were rotting in a thin

film under the paint (fungal spores are in the air, everywhere), and its bond to the wood then failed. This increased dramatically

in the fifties, when lead oxide (a white pigment) was removed from primers and paints due to growing concerns. There was no

substitute provided, and without this mild but effective preservative, even good-quality wood began to rot sooner. The faster-grown

wood used on residential and commercial building construction a few decades later had much of its natural rot-resistance bred out

of it by the lumber companies whose focus was entirely on making more lumber faster. Even the highest-quality paints were failing

sooner on wood with little rot-resistance. So, there was an abundance of failure and a complete vacuum of effective solutions. Because I am a scientist I

had the ability to observe and to understand what others could not. I was thus able to develop this modern and effective technology.

You can read more about the details of the development of my technology here. My first customers were people with rotting wood on their wood boats, in the early seventies. The Marine

environment is vastly more severe than the Architectural environment. After a decade of exceptional performance on boats, the products

spread quickly into the architectural marketplace where they easily outperformed the hundred-year-old wood-maintenance technology

and products that were all-there-were in the paint, hardware and building-supply stores. Everyone clearly understood that if it

worked on a boat, it would definitely give superior performance on a building. After forty years, word-of-mouth about Smith's Clear Penetrating Epoxy Sealer is on every construction-related

and boat-related forum where people tell others about the product. Even if they don't use the full name (I admit it is quite a

mouthful, but I believe in naming products for what they do) but only two or three of its words, it's Smith's Clear Penetrating

Epoxy Sealer that they are talking about. Look for my name on the container; that way you know it's genuine. ------Steve Smith Now, here's more information about the product, its performance in different temperatures, and the Cold Weather

Formula for use in colder weather, even down to freezing.

The long working time (pot life) of these products mean

they will retain their penetrating and moisture-dissolving ability for

more time. Working

in cooler weather? Use Smith's

Cold Weather Formula™ The Cold Weather Formula™ of Smith's Clear Penetrating

Epoxy Sealer was developed because sometimes repairs such as restoration

of deteriorated wood, repair of osmosis-damaged fiberglass boats, and/or

adhesion-promoting priming for sealants or coatings must be done in the

winter. The particular kind of resins that must be used in Smith's Clear Penetrating

Epoxy Sealer in order to obtain all its usual performance features, which

have made the product famous, do not cure well below about 50° F and

essentially stop curing by 40° F. This is a normal characteristic

of these products, and has been well known to chemists for half a century.

If used in cold weather, after a few days they cure in an incorrect manner

and do not develop optimum properties in the wood. Early in 1991 the genius in the research department of Smith & Co.

discovered the fundamental reason why this is so, and discovered Smith's

Dual Synergistic Catalyst™ which makes it possible for these resin systems

to develop a full and predictable cure at temperatures down to 28°

F, slightly below freezing! The entire formula was redesigned to take advantage of this new technology.

The new formulation behaves essentially the same in freezing weather as

Smith's Warm Weather Formula™ does in moderate weather. Smith's Cold Weather

Formula was designed to absorb as much water as the existing system does

from wood or osmosis-damaged fiberglass laminate, and in addition to dissolve

the ice crystals that form in damp materials subjected to below-freezing

conditions. The product line was further improved in 2001 when the solvent formulation

was upgraded to give a 50% increase in moisture-dissolving capabilities. Smith's Cold Weather Formula of Smith's Clear Penetrating Epoxy Sealer

mixes one-to-one by volume as does the Warm Weather Formula. Once mixed,

it is recommended that the product be used within its "pot life",

although it will be fluid for much longer. Smith's Cold Weather Formula of Smith's Clear Penetrating Epoxy Sealer

(CPES) was designed to be used in the temperature range of 28° F -

65° F. The table of pot life and full cure times below

illustrates this. It is a necessary part of the wood restoration process

that the solvents be allowed to evaporate out of the wood before paint

or filler is applied. The solvent blend in Smith's Cold Weather Formula

evaporates about as fast in cold weather as the solvent blend in Smith's

Warm Weather Formula does in warm weather. The solvent blend of Smith's Cold Weather Formula has a milder odor,

as well as evaporating about six times faster. These features allow restoration

work to be completed sooner and to be done in the winter, when most products

do not work properly. Restoration of wood inside a house, such as in a bathroom, a door threshold

or the inner part of a window sill, should be done with Smith's Cold Weather

Formula rather than Smith's Warm Weather Formula when the house is occupied,

due to the much milder odor and more rapid solvent vapor dissipation of

this version. Nighttime temperatures are usually much less than daytime temperatures

and so night provides less progress towards full cure than day. This makes

Smith's Cold Weather Formula valuable when the daytime temperatures are

in the 50° F ~ 60° F range and/or night temperatures are in the

30° F ~ 40° F range.

When is the wood dry enough for CPES? Please call us directly

for 1-800-234-0330

In 1972 I invented

Clear Penetrating Epoxy Sealer™

and the Modern Technology that

RESTORES and PREVENTS

weather-related damage to exterior wood.

Here's how it works:

"(We've handled) window sills, decking, (and) porch dry rot. (It's)

a very empowering product-having taken us off our dependence on "handy-people" who

have charged us too much for too little in such repairs, i.e., inferior results.

Homeowners-You can do this." L. M. G.

Water selectively

penetrates the sound portion of wood. Smith's Clear

Penetrating Epoxy Sealer™ (also known as CPES™)

selectively penetrates the deteriorated parts of wood. In other words, it finds the rot. There is actual SCIENCE here.

No other product uses my science.

None.

The science is why it works.

Please read Section 1.3 of

Test Methodology, Restoration of Rotted Wood

with a Flexible Penetrating Resin.

It is

common for rot to start up again behind

fillers and paints applied over old wood that had some rot already started.

Wood treated with Smith's Clear Penetrating Epoxy Sealer

resists rot starting up again.

Glu-Lam Impregnation Comparison.

Here's What Professionals Need to Know:

Section IV, paragraph 8.6 of

Restoration of Rotted Wood with a Flexible Penetrating Resin.

The natural

porosity of sound wood is almost entirely sealed by a single impregnation with

Smith's

Clear Penetrating Epoxy Sealer. This is another reason why it cures paint

failure. See what it does to a common building siding, T1-11 plywood:

T1-11 Plywood Impregnation.

Smith's Clear Penetrating Epoxy Sealer is the only product made largely from the natural resins of wood itself. It creates a tough,

flexible resin system that moves with the wood. It allows the wood to "breathe" so excess moisture does not accumulate

behind it, promoting paint-failure and ultimately rot. The experiments that demonstrate this are in Chapter 3.0, Section II,

Restoration of Rotted Wood with a Flexible Penetrating Resin.

Paint or varnish is glued to the wood with its flexible epoxy glue that stretches and bends almost identically

to natural wood. The proof of that is in the mechanical tests in Section III of

Restoration of Rotted Wood with a Flexible Penetrating Resin."I've been in the 'Period House' restoration business for more than 25 years,

and to save old windows and doors and other period house architectural items, I learned real early that

just because there was some rot, I did not have to throw out a window sash or architectural trim, if I

use Smith's Clear Penetrating Epoxy Sealer (CPES) and Smith's Fill-It Epoxy Filler.

I could not stay in business without Smith's epoxy systems." David T. Clark - I Do Windows

And Doors-Sacramento CA 916-498-1570

Smith's Clear

Penetrating Epoxy Sealer™ (CPES™) consists of a tough, flexible resin

system in a solvent blend which dissolves the sap, oil and moisture found

in wood. The resin system is derived from natural wood resin and develops

a chemical adhesive bond to the wood fibers themselves.

The wood is strengthened while allowing normal expansion and contraction

with changes in temperature and humidity.

When repairing wood that has mild dry rot, the CPES will migrate along

the abnormal porosity which dry rot fungus creates within the wood, as

long as it continues to be fed in. Impregnation of wood with CPES changes

the cellulose of wood (which fungi and bacteria find tasty and easily

digestible) into epoxy-impregnated cellulose which resists further attack

by fungi and bacteria while reinforcing the wood, accomplishing restoration.

Paint or varnish will last longer because the paint has a strongly attached,

chemically compatible surface to bond onto.

Read and follow application instructions. Keep rain or dew away from areas

being treated with CPES until solvents have evaporated out of the wood.

This will take at least a day and may take a week or more, depending on

the extent of deterioration, how deeply the CPES soaked in and the temperatures

day and night.

Application may be by brush, roller or immersion. Spraying is not recommended

as a portion of the solvent component will evaporate in transit, and it

is important that the product be applied to the wood in the same formulation

furnished originally. When applying by roller on a vertical surface, hold

the roller only horizontally and slowly roll only upwards. When treating

rot inside sound wood, drill a hole that intersects the rot, glue a funnel

in the hole, and use Smith's Cold Weather Formula™ to impregnate the region.

Allow sufficient time for solvents to diffuse and evaporate out of the

wood before applying fillers or glues. Removing paint from all sides of

wood to be treated speeds solvent evaporation, as does moving air.

CPES is also a consolidant for old, crumbly concrete or mortar between

bricks, and is an essential component of effective osmosis blister treatment

on fiberglass boats.

Our Epoxy Cleanup Solvent. will clean up any epoxy product before it cures.

Once cured, no clean-up solvent is effective.

Smith's Clear Penetrating Epoxy Sealer will prevent freeze-thaw damage

to concrete. This surprising performance was discovered by a customer

in Finland and verified by the National Testing Institute.

"Your products are the best and my first choice. Meaning if

I need something and you have a product in that line, I take yours without

even looking at what other companies offer because your products are top notch

and have a value to price ratio as good as others." Winston Lambert, Los Altos Hills, CA

U.S. retailer near you.

Visit our new website for the Modern view.